Powering a More Efficient Future for Industrial & Manufacturing

Aurelia’s advanced turbines help manufacturers cut energy waste, reduce emissions, and ensure stable, on-site power for greater resilience and efficiency.

Overview

Aurelia Technologies develops cutting-edge small-scale gas turbines purpose-built for the demanding needs of industrial and manufacturing operations. Our flagship technology, the Aurelia A400 and A800, deliver high-efficiency, low-emission on-site power and heat to help facilities improve energy reliability, reduce operational costs, and meet sustainability goals.

The Manufacturing and Industrial Challenge

Manufacturers face growing energy, cost, and reliability pressures, creating the need for:

Reducing energy costs while maintaining production continuity

Cutting carbon emissions to meet sustainability targets

Managing energy supply amid market volatility and grid instability

Improving efficiency beyond aging CHP and reciprocating systems

Increasing operational flexibility for variable production demands

Transitioning to cleaner, more resilient energy solutions

Our Solutions

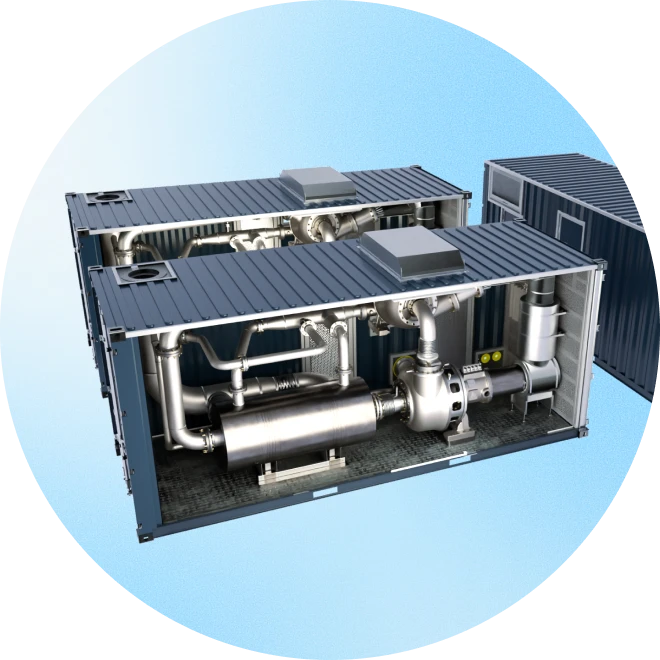

The Aurelia A400 and A800 turbines are engineered to solve these challenges with a compact, highly efficient, and fuel-flexible combined heat and power (CHP) system. Designed to integrate seamlessly into industrial energy infrastructure, it provides reliable baseload power and captures waste heat for use in process heating, steam, or hot water—boosting overall energy efficiency above 80%. Our technology is also able to run on process waste gases for a waste to power application.

Key Benefits

Smarter Power for Smarter Manufacturing

High Electrical Efficiency

Up to 40% electric efficiency—among the best in its class—reduces electricity costs and improves energy ROI.

CHP Integration

Generates useful thermal energy for process hot water or drying improving total plant efficiency.

On-Site Reliability

Provides resilient power supply for critical operations, reducing dependence on the grid and avoiding downtime.

Low Emissions

Meets or exceeds industrial NOx and CO₂ targets; ideal for companies pursuing ISO 50001 or ESG compliance.

Fuel Flexibility

Operates on natural gas, biogas, synthetic gases, or hydrogen blends—allowing for decarbonization without hardware changes.

Compact & Modular

Small footprint enables easy deployment within constrained industrial spaces or phased scaling across sites.

Ideal Applications

Aurelia’s high-efficiency microturbines produce power where and when it’s needed.

Ideal For

Food and beverage processing

Ideal For

Chemical and pharmaceutical plants

Ideal For

Textiles, pulp & paper, and packaging

Ideal For

Metal fabrication and foundries

Ideal For

Industrial parks and campus-style manufacturing

Certifications & Compliance

Built for Industrial Standards

Aurelia turbines meet CE and ISO standards and are engineered to support environmental regulations and safety protocols common in industrial and manufacturing zones worldwide. With hydrogen readiness and modular deployment, we help manufacturers future-proof energy systems while meeting today’s operational benchmarks.